COMMAND SMFI, one of the most recognized international manufacturer, is able to design and manufacture Drill Pipes designed to provide superior technical performance and a service lifetime exceeding most current industry standards.

Drill Pipe are in conformance with API 5DP, 7-1 & 7-2 specifications:

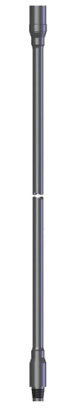

Drill Pipe Internal and External Upset Profile

One of the most critical sections in welded drill pipe is the transition zone between the tool joint and the pipe body. A smooth, gradual transition linked to the superior nature of the purity of our steel ensures minimum stress concentration and greatly improves the fatigue life of the pipe.

Drill pipes are available with:

COMMAND-SMFI also has its own tool joint manufacturing capabilities and our tool joints meet or exceed API specifications and tolerance requirements. Each joint is inspected to guarantee visual and dimensional properties and tested to ensure proper mechanical characteristics.

All tool joints are: